Wildeck is no stranger to creating mobile platforms at its Goodyear, AZ, manufacturing facility. However, the task of designing-in wheel casters on a platform becomes increasingly less of a viable solution as structures become larger or heavier. That is why Wildeck partnered with Airfloat to develop a creative alternative for the end user customer, by use of air caster technology.

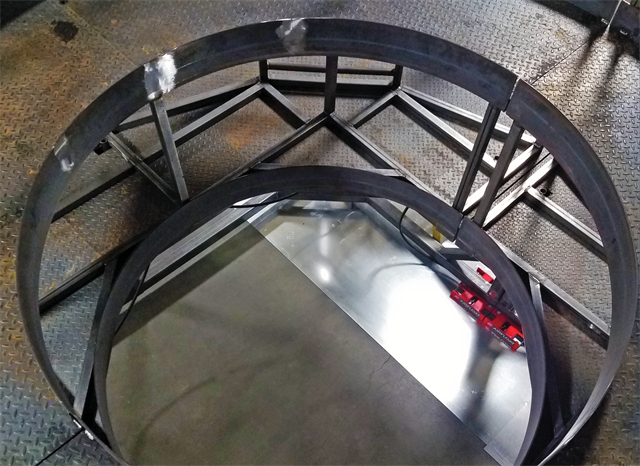

Wildeck was looking for an alternative to wheels to move a newly-build aerospace work stand for its end user customer in the aerospace industry. The work stand was about 14 ft. x 14 ft., weighed five tons and was difficult to move on wheels. Since the customer was already utilizing air-assisted material handling in their plant, the infrastructure needed to support air casters was in place, making them the most viable solution for the maneuverability issues.

Due to the heavy weighted steel construction of Wildeck’s access platform, it was necessary to rely on air caster technology to float the load on air. Air casters made it possible to move the work stand with the power of just two personnel. The work stand was mounted on the air skids to permanently keep the work stand in place and make it safer for workers to maneuver.

Air caster technology allowed the work stand to move with just two workers, granting the ability to permanently mount the work stand on air skids. The work stand could freely be moved around the end user customer’s facility and the air skids were easy to use.